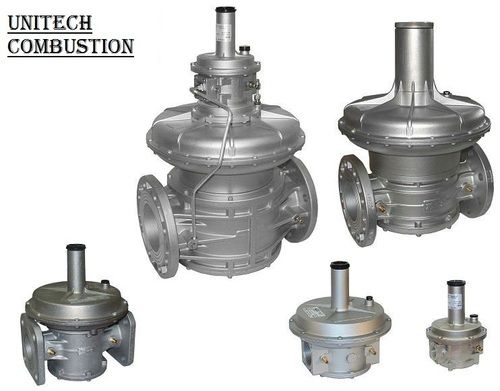

Krom Schorder Pressure Regulating Valve

Krom Schorder Pressure Regulating Valve Specification

- Seal Material

- NBR (Nitrile Rubber)

- Sensor Type

- Diaphragm

- Grade

- Industrial

- Bourdon Tube

- No

- Outer Size

- Standard

- Thread

- BSP/NPT

- Material

- Aluminum Alloy

- Dial Material

- Aluminum / Plastic

- Pointer Material

- Aluminum

- Processing Type

- Precision Machined

- Diameter

- Up to 120 mm

- Mount Type

- Inline or Panel Mount

- Scale Range

- 0.5 to 500 mbar

- Accuracy

- 1.5% FSO

- Finishing

- Powder Coated

- Measure Pressure Of

- Gas

- Accessories

- Mounting Brackets, Installation Manual

- Outlet Pressure Setting

- Adjustable

- Connection Size

- 1/2'' to 2''

- Response Time

- <1 s

- Flow Rate

- Up to 150 m³/h

- Conformity

- EN88, CE Certified

- Model

- Pressure Regulating Valve

- Protection Class

- IP54

- Inlet Pressure

- Max. 500 mbar

Krom Schorder Pressure Regulating Valve Trade Information

- Minimum Order Quantity

- 1 Piece

- FOB Port

- Ahmedabad

- Payment Terms

- Telegraphic Transfer (T/T)

- Supply Ability

- Piece

- Delivery Time

- Ex stock Days

- Main Domestic Market

- Himachal Pradesh, Andaman and Nicobar Islands, Uttarakhand, Daman and Diu, South India, East India, Assam, Arunachal Pradesh, Bihar, Chandigarh, Delhi, Gujarat, Goa, Jammu and Kashmir, Jharkhand, Karnataka, Madhya Pradesh, Maharashtra, Mizoram, Meghalaya, Manipur, Punjab, Pondicherry, Rajasthan, Sikkim, Tamil Nadu, Telangana, Tripura, West Bengal, Kerala, Nagaland, Dadra and Nagar Haveli, Lakshadweep, Uttar Pradesh, Haryana, North India, Andhra Pradesh, Central India, Odisha, West India, Chhattisgarh, All India

About Krom Schorder Pressure Regulating Valve

With the strong backing of experts, our organization is affianced to manufacture and supply Krom Schorder Pressure Regulating Valve. The offered valve is precisely manufactured by our dexterous professionals using utmost quality metal alloys and pioneering techniques. This valve is specifically constructed to attain ease in regulation of fluid flow within the installed machinery and equipment. Besides this, the provided Krom Schorder Pressure Regulating Valve can be purchased from us in several specifications at marginal prices.

Features:

-

Robust construction

-

Easy installation

-

Low turning torque

-

Longer functional life

Specifications:

-

Low and medium pressure regulators

-

High regulating precision with various types of gaseous media

-

Inlet pressure up to 60 psig

-

Springs available for outlet pressure adjustments

-

Outlet pressure adjustment up to 100 inch WC

-

Sizes from 1/2 inch to 4 inches

-

Outlet pressure cut off

Exceptional Pressure Control for Gas Applications

Engineered for accuracy and reliability, the Krom Schorder Pressure Regulating Valve ensures stable gas flow and pressure control. Its industrial-grade, diaphragm-based sensor ensures a rapid response time of less than one second, making it suitable for demanding environments. Safety is prioritized with EN88 and CE compliance, IP54 protection, and high-precision performance.

Flexible Installation and Wide Compatibility

With thread options in BSP and NPT, as well as inline or panel-mount capabilities, this valve fits seamlessly into varied industrial setups. The aluminum alloy construction and robust sealing system withstand rigorous demands, while included accessories, such as mounting brackets, simplify installation processes.

Reliable Performance for Critical Operations

Ideal for gas systems, the valve maintains outlet pressures with 1.5% FSO accuracy across a broad scale range. Its powder-coated finish, durable materials, and protection class ensure long-term service, while the adjustable controls allow for tailored pressure management in multiple industrial contexts.

FAQs of Krom Schorder Pressure Regulating Valve:

Q: How do I adjust the outlet pressure on the Krom Schorder Pressure Regulating Valve?

A: The outlet pressure can be easily set within a range of 0.5 to 500 mbar using the adjustable control built into the valve. Refer to the included installation manual for precise adjustment guidelines tailored to your application.Q: What types of gases can this pressure regulating valve manage?

A: This valve is specifically designed to measure and regulate the pressure of various industrial gases, thanks to its robust NBR (Nitrile Rubber) seals and aluminum alloy construction. Always consult your gas type compatibility before installation.Q: When should this pressure regulating valve be used in a system?

A: Deploy this valve in any industrial gas line needing controlled, stable outlet pressure, especially where accurate, rapid response is critical, such as in manufacturing, processing, or HVAC installations.Q: Where can the Krom Schorder Pressure Regulating Valve be installed?

A: The valve can be installed inline with piping systems or panel mounted, depending on your setup requirements. It supports both BSP and NPT thread connections and is suitable for use in environments requiring up to IP54 protection.Q: What is the process for installing this valve?

A: Installation involves securing the valve using the provided mounting brackets and following the step-by-step procedures outlined in the included manual. Ensure threading compatibility (BSP/NPT), and always check system pressure and leak integrity after installation.Q: How does the diaphragm sensor benefit industrial applications?

A: The diaphragm sensor delivers precise and rapid regulation (under one second response), ensuring consistent gas flow, which is vital for processes requiring stable pressure without delay or fluctuation.Q: What are the advantages of the valves robust construction and certifications?

A: Its precision-machined, powder-coated aluminum alloy body ensures durability and resistance to harsh conditions, while EN88 and CE certifications signify adherence to strict performance and safety standards for industrial environments.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Regulator And Pressure Gauage Category

Madas Pressure Regulator Valves RG/2MC DN 25/40/50/65/80/125

Price 5000 INR / Piece

Minimum Order Quantity : 1 , , Piece

Finishing : Matte, Galvanized

Measure Pressure Of : Gas

KROM SCHORDER SAFETY SHUT OFF VALVE JSAV-50

Price 50000 INR / Piece

Minimum Order Quantity : 1 , , Piece

Finishing : Matte

Measure Pressure Of : Gas

Thread : NPT internal thread

Krom Schorder Air And Gas Pressure Ratio Controller GDJ40R04

Price 22500 INR / Piece

Minimum Order Quantity : 1 , , Piece

Finishing : Matte

Measure Pressure Of : Gas

Thread : Rp to ISO 71.

Krom Schorder Air And Gas Pressure Ratio Controller GDJ15R04

Price 15000 INR / Piece

Minimum Order Quantity : 1 , , Piece

Finishing : Matte

Measure Pressure Of : Gas

Thread : Rp to ISO 71.

Send Inquiry

Send Inquiry

Send Inquiry

Send Inquiry Send SMS

Send SMS Call Me Free

Call Me Free