ECEE Make Thermax Boiler Sequence Controller MA 150.01

ECEE Make Thermax Boiler Sequence Controller MA 150.01 Specification

- Pressure

- Suitable for boiler operating pressures up to 30 bar

- Accuracy

- High switching accuracy for burner flame detection

- Function

- Automatic sequence controller for Thermax boiler burners

- Size

- 125mm x 75mm x 60mm (Approx.)

- Temperature Range

- 0°C to 60°C

- Model

- MA 150.01

- Make

- ECEE

- Power Supply

- 220V AC, 50/60Hz

- Mounting Type

- Panel mounting

- Protection

- Overload and short circuit protection

- Indicator

- LED status indicators for sequence

- Control Output

- Relay output for burner on/off

- Application

- Industrial Thermax boilers

ECEE Make Thermax Boiler Sequence Controller MA 150.01 Trade Information

- Minimum Order Quantity

- 1 Piece

- FOB Port

- AHMEDABAD

- Supply Ability

- 100 Pieces Per Day

- Delivery Time

- 15 Days

- Main Domestic Market

- All India

About ECEE Make Thermax Boiler Sequence Controller MA 150.01

Ecee Thermax Boiler Sequence Controller MA150.01

Unitech Combustion, Ahmedabad Importer and suppliers of Thermax boiler spare parts such as Burner rod, Burner Rod Coil, Adaptor, Burner Plate, Diffuser disc, Nozzle assembly, Photocell, U.v detector, H.t.Lead, Ignition Transformer, Ignition Electrode, Sequence controller, Photocell holder, Pressure switch, Ecee Petercem Sequence controller/ Photocell/ Photoresistors for Thermax Boiler.

We Import and supply following different models:

- Ecee Thermax boiler control Box MA810

- Ecee Thermax boiler control Box MA150.01

- Ecee Thermax boiler control Box Ma 55.

- Petercem Thermax boiler Ecee photocell/ photo resistors 8205

- Ecee Thermax boiler photocell/ photo resistors 8209

- Wiring Base plate for Ecee MA810

- Wiring Base Plate for Ecee MA150.01

- Wiring Base plate for Ecee MA55

We also do repairing for Petercem Ecee Sequence controller Ma 810/ Ecee Ma 150.01, Ecee Ma 55 etc.

Automated Burner Management

The MA 150.01 sequence controller automates the startup, operation, and shutdown of Thermax boiler burners, ensuring safe and efficient performance. LED indicators provide real-time sequence status, enabling operators to monitor every operational stage with clarity and confidence. Using this device simplifies regular maintenance routines and reduces manual intervention.

Rugged Design for Industrial Applications

Built to withstand demanding industrial environments, this controller features robust overload and short-circuit protection. The compact panel-mount design (125mm x 75mm x 60mm approx.) enables easy integration into existing systems, making it ideal for upgrades or new installations in any industrial Thermax boiler infrastructure.

FAQs of ECEE Make Thermax Boiler Sequence Controller MA 150.01:

Q: How does the MA 150.01 Sequence Controller manage burner operation in Thermax boilers?

A: The MA 150.01 automatically switches the burner on and off based on the programmed sequence, ensuring correct ignition, monitoring for reliable flame detection, and providing LED status updates for each stage. This increases both safety and efficiency during boiler operation.Q: What protection features does the MA 150.01 offer during operation?

A: The controller comes equipped with built-in overload and short circuit protection, safeguarding the system and connected devices from electrical faults or abnormal operating conditions.Q: When should you use the MA 150.01 controller for your boiler?

A: Install the MA 150.01 controller when you require precise and automatic sequencing of Thermax boiler burners, particularly in industrial settings where reliable and safe operation under pressures up to 30 bar is critical.Q: Where is the MA 150.01 controller installed in a boiler system?

A: This model is designed for panel mounting, allowing integration inside control panels close to the boiler system for centralized control and easy access by operators or technicians.Q: What is the process for setting up the MA 150.01 controller?

A: Setup involves panel mounting the controller, connecting the 220V AC power supply, and wiring the relays to the burner system. Once installed, the LED indicators and protection features assist in monitoring and troubleshooting during operation.Q: What are the key benefits of using the MA 150.01 in industrial boiler applications?

A: Benefits include highly accurate burner flame detection, automated control improving operational safety, reduced manual oversight, and enhanced protection against overloads and short circuits. Its reliable performance ensures long-term value for industrial boiler operations.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Sequence Controllers Category

Temprature controller KS 40-108-9090 M-D-35

Price Range 2000.00 - 5000.00 INR / Unit

Minimum Order Quantity : 1 Piece

Pressure : Not applicable (Temperature controller)

Accuracy : 0.5% of measuring range

Size : 48 x 96 mm (DIN 43700 standard)

Connection : Screw terminals for secure wiring

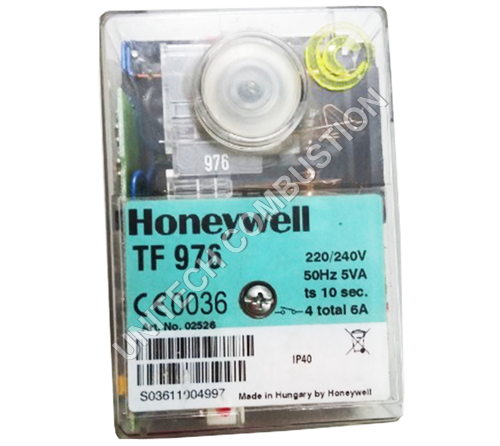

Sequence controller TFI 976

Price Range 2000.00 - 5000.00 INR / Unit

Minimum Order Quantity : 1 Piece

Pressure : Up to 20 bar

Accuracy : 1% of full scale

Size : 96 mm x 96 mm

Connection : Screw terminals

Burner Sequnece Controller LME 22.331 C2

Price Range 2000.00 - 5000.00 INR / Unit

Minimum Order Quantity : 1 Piece

Pressure : Atmospheric pressure operation, not directly exposed to process pressure.

Accuracy : Reliable operation according to EN 298 standard.

Size : 96 mm x 96 mm x 108 mm (L x W x H)

Burner Controller LMV 52

Price Range 2000.00 - 5000.00 INR / Unit

Minimum Order Quantity : 1 Piece

Pressure : Designed for typical burner operation; consult datasheet for maximum allowable pressure ratings

Accuracy : High accuracy with consistent and reliable burner performance

Size : Compact module, suitable for electrical panel mounting (approx. 225 mm x 130 mm x 55 mm)

Send Inquiry

Send Inquiry

Send Inquiry

Send Inquiry Send SMS

Send SMS Call Me Free

Call Me Free